We are different

1 Design and manufacture of machinery for our own use

We both design and manufacture everything we need using our own methods wherever possible. We provide the solutions to our specific requirements, guided only by our own judgement, without resorting to any kind of outside assistance

Why do we undertake the design and manufacture of machinery for our own use ?

We both design and manufacture everything we need using our own methods wherever possible. We provide the solutions to our specific requirements, guided only by our own judgement, without resorting to any kind of outside assistance

Why do we undertake the design and manufacture of machinery for our own use ?

1 ) We believe that there is no one who knows our specific needs better than we do and that is why we are the best equipped to find solutions

2 ) As designers and manufacturers of our own machinery, both maintenance and possible repairs are carried out by us. This allows us not to have to depend on third parties

3 ) At the same time we learn and gain technical knowledge, which would not occur if we entrusted the task of solving our needs to outside professionals. Moreover, entrusting this work to others does not guarantee that it will be carried out successfully

Below some of the machines that we have designed and built ourselves can be seen

1.1 Machines to cut pieces of artificial grass to size

Artificial grass rolls are manufactured to a length of 20-25 meters. Due to the enormous demand for pieces of a shorter length, it was essential to have machines capable of automatically cutting pieces to size. This avoids the work having to be carried out manually, with the unrolled material on the floor, by two people equipped with only a simple cutter, a tape measure and a cutting ruler. This is now done by machines capable of unwinding the rolls and then immediately rewinding the material again while it is being measured. Once the desired size is reached, it is cut, sealed and packed, all this is carried out automatically

We have designed and manufactured five types of machine in their entirety for this purpose. Below we show some videos of these machines in operation

Machine to cut 2 and 4 meter wide pieces of artificial grass to size

Machine to cut 2 meter wide pieces of artificial grass to size

SUMIGRAN has developed some home made machines to cut artificial grass and carpets to length

SUMIGRAN´s home made machine to cut artificial grass and carpets to length

1.2 Carpet strap cutting machine for our REXMAT aluminium mats

The upper carpet insert of our REXMAT aluminum mats is obtained by cutting the material into 22 mm wide strips from 1 or 2 meter wide rolls. It was essential to have a machine capable of unwinding the parent roll, cutting it into strips, and then rolling up each of the resulting strips. We have fully designed and manufactured a machine for such a purpose. You can see a video of the machine in operation by clicking here

2 Design and manufacture of logistics solutions for our own use

Regarding the logistics of our warehouses, we have also developed and even manufactured our own solutions, which from experience we know are the most suitable for us

2.1 Dynamic storage system using stackable stillages

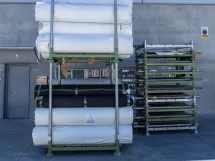

We have developed and manufactured our own stackable and foldable stillage with an internal dimensions of 200x200x200cm, which allows us to store up to 30 rolls ( depending on the diameter ) of 2 meters

Likewise, we also have a large number of stackable stillages of a smaller standard model, which can contain up to 12 rolls ( depending on their diameter ) of 2 meters

Why stackable stillages ?

1 ) Mainly to make the most of the volume of our warehouses, which are by far our largest investment due to their high cost

Stackable stillages are dynamic storage systems. Static systems such as conventional racks require a lot of “dead” space between racks, so that forklifts can both load and unload the rolls, which can be 2 or 4 meters long. These “dead” spaces represent a lot of wasted warehouse space. With dynamic storage systems, free spaces for forklift traffic are reduced to a minimum. Stillages can be stacked in columns one behind the other, with no space between them

2 ) When unloading a truck from the factory, each roll is immediately deposited in a stackable stillage. Once filled, it is transferred to the warehouse space reserved for the artificial grass model it contains. In this way, to move all the rolls that each stillage contains, only one movement is necessary, saving us a lot of time. Otherwise, each roll would have to be transported individually from the truck to its place in the warehouse, which would increase labour

3 ) When loading a truck, we place a stackable stillage full of rolls next to it. Each roll is collected from the stackable stillage and is then loaded into the truck. In this way, the rolls that each stillage contains are moved at once, saving us a lot of time. Otherwise, each roll would have to be transported individually from its place in the warehouse to the truck, which would increase labour

2.2 Loading and unloading docks of our own design and manufacture

None of our current warehouses have loading docks which put the warehouse floor at the same level as the floor of the truck in order to gain access to the inside of the vehicle directly from the warehouse with forklift trucks in order to load or unload. However, It was essential for us to be able to gain access to the interior of the truck with a forklift. To achieve this, we designed our own loading and unloading docks, which in combination with our metal stillages greatly simplify our work

3 Meticulous in the care and handling of artificial grass. Nobody takes as much care as SUMIGRAN

1 ) In each of the cells of our conventional shelving racks designed to store 4-metre rolls, the heavy weight of the upper rolls generates significant pressure on the lower rolls, causing them to put pressure on the sides of the cell. This is why in our premises these are specially equipped with expensive completely smooth side boards, to avoid marks, wrinkles or deformations that the edges of the racks due to their rectangular shape would cause if these boards were not there

2 ) For the same reason i.e. to prevent possible marks, wrinkles or deformation of the material due to pressure being exerted against the edges or projections, the sides of each of our larger-sized stackable stillages are equipped with expensive, completely smooth metal plates, avoiding edges that would inevitably cause marks on the material

3 ) In the case of our smaller sized stackable stillages, the sides are round tubes, to avoid edges that could scrape the material

4 ) Our forklift trucks are equipped with various types of carpet boom attachments to easily handle the rolls. It is only necessary to insert the boom into the inner hollow core of the roll for handling. Rolls being handled with conventional pallet forks that generally equip forklift trucks is a frequent cause of damage to material

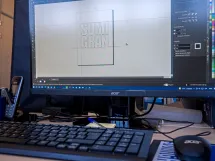

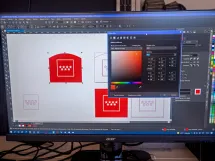

4 Our own company image design

We also have the material and human resources that allow us to both develop and edit our website, our technical catalogues, and everything related to our company image, such as, logos, commercial brands or marketing campaigns. All this is done using strictly our own criteria, without any kind of outside assistance or advice